Steel wire rope

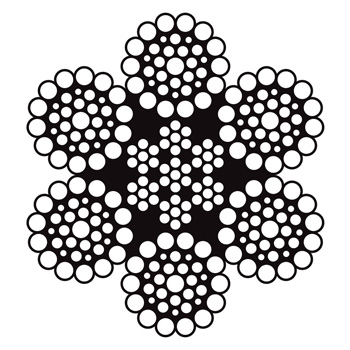

Steel wire rope consists of a number of strands and wires that are wrapped around a core in regular geometric shapes, and in choosing the right steel wire rope in cranes, lifts and various industries, the following points should be considered.

1-The diameter of rope:

(Dia) which is stated in millimeters "mm" or inches "" "which must correspond to the drum groove of the device.

2- Steel wire rope structure: Construction which is selected according to the function of the device and its application in cranes.

6x7, 7x7 , 6x12+7FC, 6x24+7FC, 6x17, 6x19, 6x25, 6x26, 6x35, 6x36, 6x37, 6x39, 6x41,

8x19, 8x25, 8x36, 8x37, 8x41

17x7, 18x7, 19x7, 35x7, 39x7, 40x7

(Seal, Warrington, standard, Filler) and other different structures

3- Type of Fiber core(FC) or IWRC

4- Type of twist, right turn and left turn

RHOL – LHOL – RHLL- LHLL

5- Type of grade or tensile:

1370, 1570, 1660, 1770, 1860, 1960, 2160, 2400 N/mm2

IPS, EIPS, EEIPS

6- Galvanized, non-galvanized, stainless steel (depending on the environment)

Hot Deep Galvanized

Galvanized

S304- S316L

7- Lubricant or non-lubricant

8- Minimum Breaking Load

MBL (Minimum Breaking Load): (Lbs, KN, ton)

9- Standard for producing steel wire rope

USA API9A, UK BS, Germany DIN, Japan JIS, Russia GOST

Elevator Wire Rope

Elevator Wire Rope Excavating Wire Rope

Excavating Wire Rope Non-rotating wire rope

Non-rotating wire rope Guy Strand

Guy Strand Mining Wire rope

Mining Wire rope Poultry Wire Rope

Poultry Wire Rope Crane Wire Rope

Crane Wire Rope  Cable Control Wire Rope

Cable Control Wire Rope lifeline safety steel Wire Rope

lifeline safety steel Wire Rope Sling Wire Rope

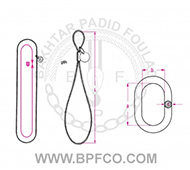

Sling Wire Rope Grommet

Grommet wire rope sling

wire rope sling woven wire rope sling

woven wire rope sling PC Strand

PC Strand Wire Rope safety barrier

Wire Rope safety barrier telecabin and telesiege wire rope

telecabin and telesiege wire rope